Fit for the laws of tomorrow!

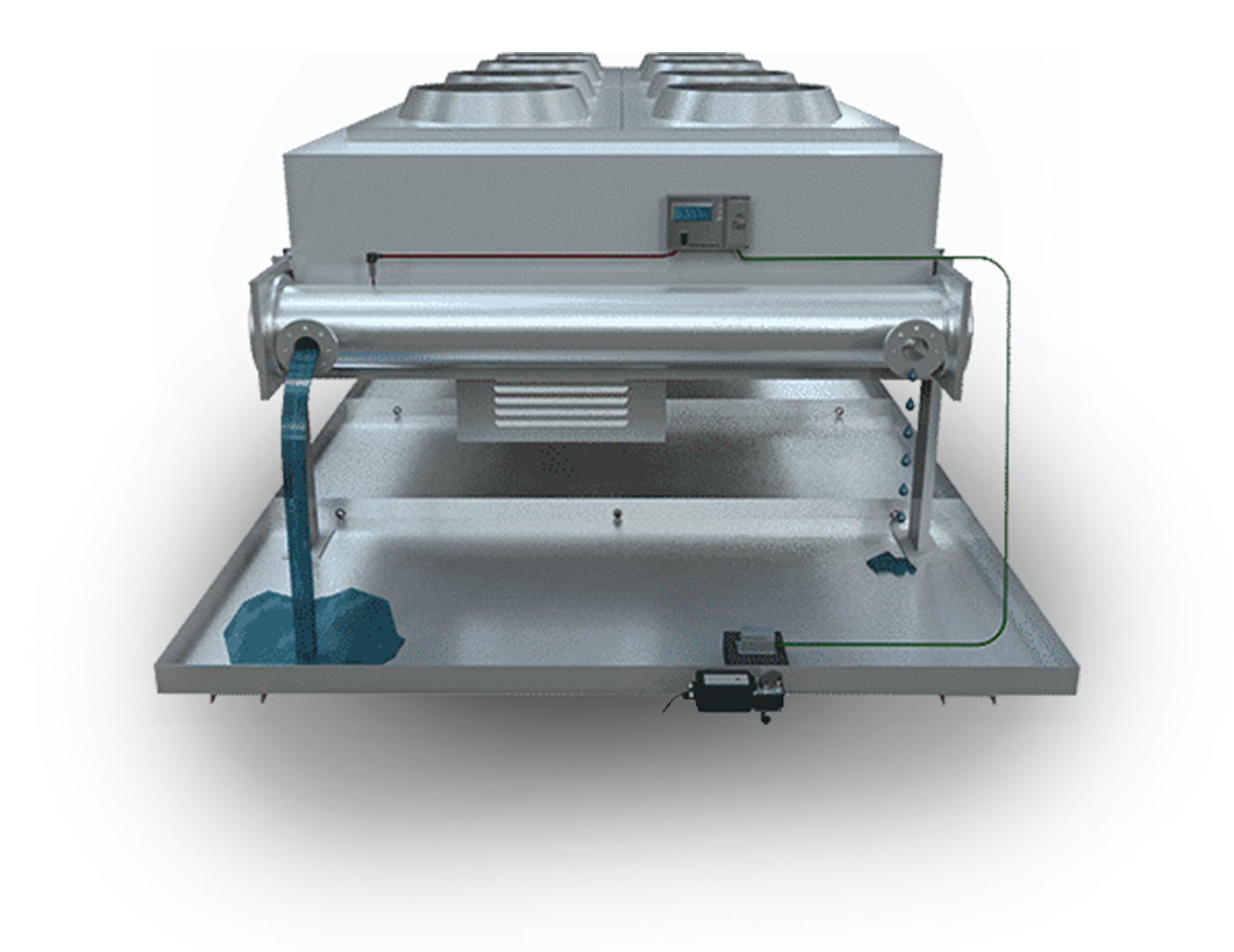

The AuRü LW – our premium product with an all-round carefree package

The AuRü LW was developed on the basis of draft legislation from the German government and the European Union and already fulfills the future requirements that legislators will place on operators. You can find out exactly what these are in the section

Legal regulations

section. It is a hybrid of AuRü W and AuRü L. The system works with a separator system that separates the oil from the water in accordance with the law and with electronic components consisting of a pressure sensor, water level sensor, glycol sensor, control box and connected fast-closing valves that are responsible for glycol protection. For open systems or circuits with a pressure equalization function, the AuRü LW should definitely be used, as it also has a glycol sensor which, in addition to pressure monitoring, can also detect small leaks (drip and splash water losses). The valves are closed when de-energized so that the tray system is closed even in the event of a power failure.

AuRü LW consisting of

Glycol monitoring

With the AuRü LW, the system is monitored by three sensors that work together to provide maximum safety. A pressure sensor, a glycol sensor and a water sensor are used.

The pressure sensor continuously monitors the pressure of the water-glycol circuit, while the glycol sensor records the composition of the medium in the tray system. The water sensor checks whether there is any water in the tray system and only switches on sensors and heaters when they need to work.

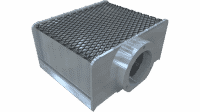

Oil monitoring

In addition to the electronic components of the AuRü LW, a completely redesigned oil separator is also used, which mechanically separates the oil from the rainwater in accordance with the law. Coarse dirt particles and leaves are kept away from the separator by a special leaf guard, so that its function cannot be impaired.

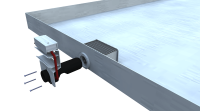

Fast-drivevalve

Speed is not always everything – but not when it comes to safety systems. Since it has been established that drip and splash water losses in systems must also be retained, we have used a valve in our AuRü LW that closes in less than a second – this is the only way to ensure that no water-polluting substances can escape before the closing process is complete.

High-performance heating insert

The high-performance heating insert (HHE) can be installed in the separator in an impact-resistant and secure manner and is firmly bolted to the collection tray.

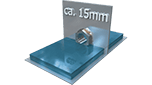

Standard hollow screws

The collection trays of the AuRü LW are connected to each other with so-called banjo bolts. These contribute to the stability of the sump construction and also enable a balanced water level in all connected sumps. The medium entering the sumps passes through the banjo bolts and is distributed equally in all connected sumps.

Please note that areas that pose a health risk, such as hospitals, doctors’ surgeries, etc., cannot be fitted with standard banjo bolts, as bacteria and algae can form in the water remaining in the tray, which can then enter the building via the ventilation system. To rule this out, a project-specific solution is required.

Switching electronics

The control electronics of the switch box used in the AuRü LW takes over the complete switching of the individual components and regulates the interaction of the respective electronic components. In the event of a pressure drop, the connected valves are closed and an alarm is sent to the building management system (BMS). The switching electronics rely on a potential-free alarm transmitter.