Fit for the laws of tomorrow!

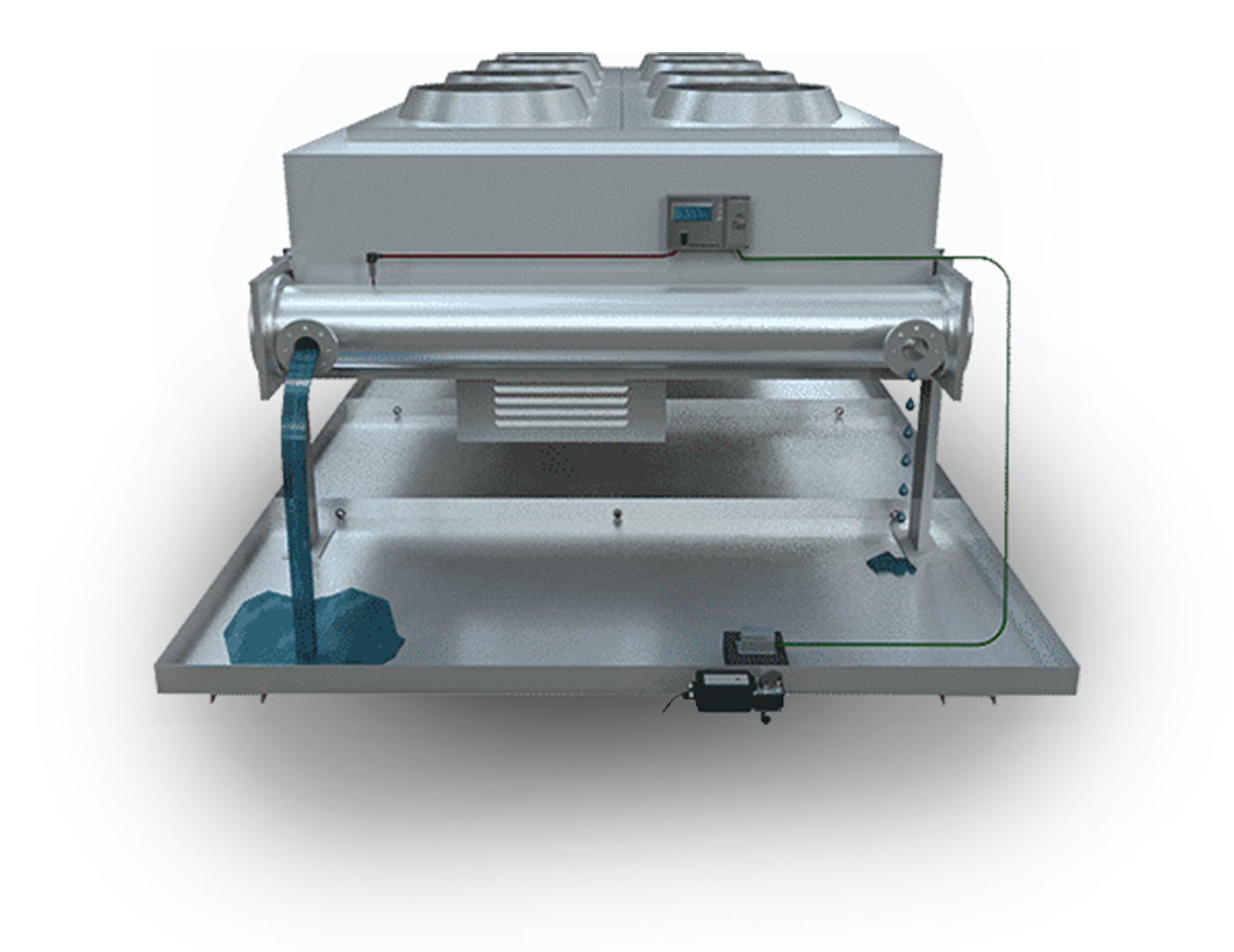

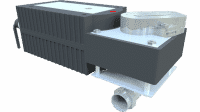

The AuRü W – our premium product in the glycol retention segment

The AuRü W was developed on the basis of draft legislation from the German government and the European Union and already fulfills the future requirements that legislators will place on operators. You can find out exactly what these are in the section

Legal regulations

section.

Optional accessories for the AuRü W

We also offer a wide range of useful accessories for your glycol protector to further increase its functionality. These include various heating systems: a heating mat with an external thermostat or a trapezoidal drain heating system that can be safely integrated into the separator in a shock-resistant manner. Also available is our special Flex-O-Frame system – optionally with ball joint – with which you can easily adapt the drip tray to local conditions.

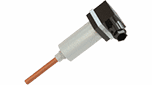

Glycol monitoring

The glycol sensor and glycol scanner react to minute amounts of glycol in the water. The glycol sensor detects these low quantities thanks to its gas/diffusion sensor principle and passes the measured values on to the switching electronics. The glycol scanner detects the medium by sonic measurement. The type of glycol used can be used by the intelligent control system for precise evaluation, thus achieving an optimum measured value.

KWS connection technology (no water level)

Our collection trays are connected to each other with so-called banjo bolts. These contribute to the stability of the sump construction and also enable a balanced water level in all connected sumps. The medium entering the sumps passes through the banjo bolts and is distributed equally in all connected sumps. The KWS tray connection stands for “no water level” and is designed so that no water level can form in the tray – it is only possible that small puddles can form in the tray area.

FastDrive valve

The AuRü Fast-Drive valve is connected to the drain of the tank system and closes within one second when a leak is detected.

Switching electronics

The control electronics of the control box used in the glycol protector takes over the complete switching of the individual components and regulates the interaction of the respective electronic components. In the event of a pressure drop, the connected valves are closed and an alarm is sent to the building management system (BMS). The switching electronics rely on a potential-free alarm transmitter.